|

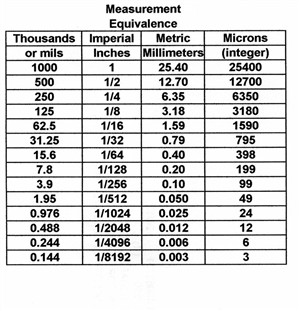

Small distances, in the metric system are traditionally measured in microns or 1/1,000,000 of a meter. Small distances in the imperial system are traditionally measured in mils or 1/1,000 of an inch. With the conversion factor of 2.54 centimeters per inch we are able to compile the table of measurement equivalence at the left.

Examination of opaque surfaces or objects that do not transmit light requires the use of special techniques. At low powers of magnification the viewing lenses are usually at a distance far enough from the object being examined so that room light or high intensity lamps can be used to illuminate the surface being examined. For higher powers of magnification the lens must be much closer to the surface being observed and the microscope and lens block the light needed to see the surface. High powers of magnification for opaque materials are obtained by a technique known as vertical illumination in which the viewing lens itself provides the light required to illuminate the subject.

Although microscopy and integrated circuitry have radically altered the time required to capture and edit magnified images and the powers of magnification available are large, if required, the majority of civil forensic science problems are often solved with low to moderate degrees of image magnification.

|