Furnace Element Failures

High temperatures such as those used to heat-treat ceramics and certain types of metal parts can create conditions under which unusual or unexpected chemical reactions can occur. Temperatures in the red to white heat range often require specialty metal, semiconductor or composite electric resistance heating elements.

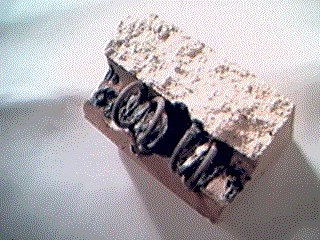

Traditional introductions to chemistry teach that the oxides of metallic elements are basic in nature while the oxides of non-metals are considered acidic. High temperature furnaces using exotic material heating elements wound or cast into appropriately sized and shaped heater elements are often supported by ceramic forms manufactured from refractory oxides such as silica, alumina or magnesia. As the temperature of the heater elements and furnace increases the acidic metal oxides on the surfaces of the furnace components can react with the basic oxides in other components. The acidic and basic oxides can form a flux and cause the components to liquefy well below their expected melting points. Unexpected reactions such as these fusions can cause significant damage to furnaces and create substantial production losses and maintenance costs.

Furnace elements fused with ceramic support.

Care must also be exercised in the use of high temperature furnaces so that materials detrimental to the furnace are not released by the materials being heat-treated.